Evolution Chassis for Griffith and Chimaera

Our Evolution chassis is on the road, tested and proven with several cars both Griffiths and Chimaeras now finished and in customer’s hands. We are currently building cars 008 and 009 and taking orders for cars 010 and onwards.

Building on the success of our improved standard chassis and further wanting to improve the materials, design and ultimately the handling capability we embarked on a virtual complete redesign of the existing chassis. Using suspension modelling software, we analysed the current geometry data of the Griffith, Tuscan and Sagaris in order to assess each car and analyse the improvements and developments TVR had made.

Geometry Improvements

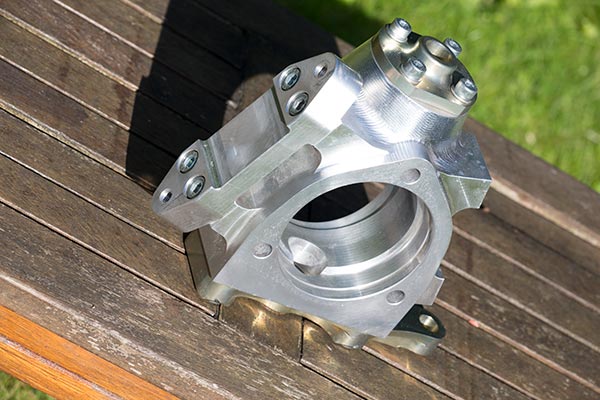

The software allowed us to model the steering geometry, camber, castor and roll centres to produce an even better set up. In order to achieve this in reality we knew we had to rid the car of its Ford front hub carrier, originally designed to be used with a Macpherson strut it is compromised in a wishbone suspension set up and gives far too much steering axis inclination.

We had initially planned to use the Tuscan alloy hub carrier and modelled this in the software to find that TVR had significantly reduced the inclination of the steering axis down to 5 degrees; we calculated the geometry around this but found better results with a slightly higher figure of 7 degrees so from this analysis we developed our own new billet alloy hub carriers for the front and also the rear, these carry the Tuscan 5 stud hub/bearing unit and the geometry is modelled around 18” wheels with the TVR Spider wheel in mind although any wheel and tyre combination with the correct overall size and offset can be used.Our hub carriers are designed to carry AP Racing CP6600 calipers with a 330mm front disc and Sagaris spec 298mm rear disc and standard rear caliper.

Roll Centre Analysis

We then analysed the roll centre height and found that TVR had progressively raised it through the years, the Griffith’s original setting was way too low causing excessive sideways migration of the roll centre, the Sagaris having highest of all had the least dramatic roll centre migration of all the cars, we again went slightly further and found even better results.

Roll centre tuning is one of the most under-utilised adjustments on a car, but one of the most powerful. This is because the roll centre has an immediate effect on a car’s handling, whereas anti roll bars, dampers and springs require the car to roll before they produce an effect, the problem is to adjust the roll centre you actually have to move the orientation of the wishbone pick up points so very difficult to do on an already made chassis, but we had a blank sheet.

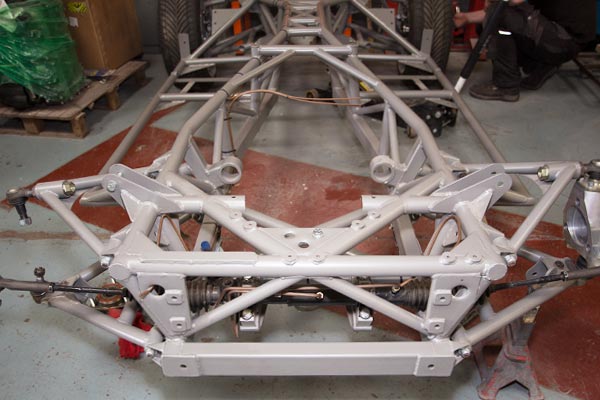

Increasing Torsional Stiffness

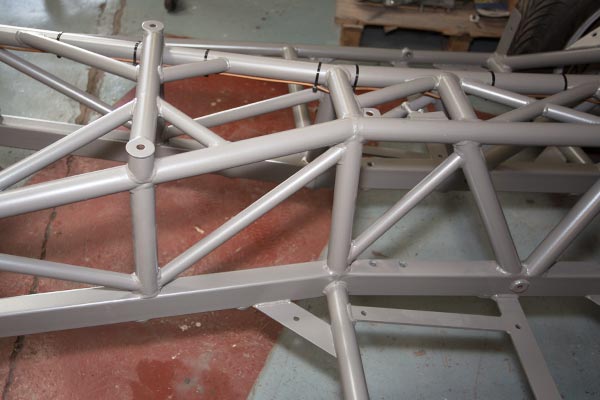

Another area to address was the poor torsional stiffness of the standard chassis, with careful measuring of body clearances we found that the main backbone structure of the chassis could be widened significantly with only minor modifications to the body shell. The intermediate tubes between the top tubes and bottom rails have been increased by three per side and an improved arrangement of opposing tubes has been achieved, rather than tubes that follow the same direction, as in the front section of the original chassis. More bracing tubes have been added particularly around the engine bay and transmission tunnel area which is one of the main areas of flex in the chassis and the diameter of the main cross brace tubes underneath the front of the engine and those around the diff have been increased from 25mm to 38mm. Wherever possible tubes have been formed and bent into shape, the top tubes are formed in only 2 sections rather than the original 5 cut sections butt welded together.

Material Improvements

Materials have been dramatically improved, no more seamed pipe, all tubes are CDS Aerocom 33 grade seamless and can even be specified as T45 grade tube if required, chassis’ are MIG welded as standard but TIG can be specified if required at additional cost.

Main tube and box sizes are as original, 38mm tube and 60×40 box, however, the main box section wall thickness has been increased from 2mm to 2.5mm and a round corner section box selected as this resists twist much better than the sharp square section original. We have also added steel seat frames into the chassis to carry the seats rather than just fixed through the fibreglass. All this and with the addition of our existing CDS roll hoop gives a dramatic improvement to the torsional stiffness and impact protection of the chassis.

You may think all this extra steel adds weight, it does, but we believe the trade off is worth it, plus whilst we are adding “sprung” weight to the main chassis, by replacing the heavy front and rear uprights with billet alloy items we have reduced the un-sprung weight, which is what really affects handling and grip.

Wishbones, Hubs, Steering and Damping

Having now placed our main tubes and beams at wider points gives other benefits. Wishbones can be shorter and with more compact hub carriers set further into the wheels, there is more space to mount the dampers in a much better, more upright position, wider top tubes giving us a wider and higher pick up point allowing a longer less inclined damper giving improved damping and spring rate control and a much improved wheel travel to damper movement ratio.

Our wishbones are all tubular items again in CDS tube and incorporate an in-situ camber adjustment system which allows accurate incremental adjustment rather than the original rudimentary sliding a ball joint clamped by two bolts.

Anti roll bars have been redesigned and the front bar has increased in diameter from 22mm to 25mm and our rear bar is very similar in design to the Tuscan item spanning the full width of the suspension and picks up on the widest point of the lower wishbone giving the bar a much greater effect than the more inboard mounted original.

Custom Damper Design

Our new damper mount positions allowed us to use longer dampers than were available for any other TVR so new dampers were specifically developed for our chassis in conjunction with our own spring rates and having virtually eliminated roll with our roll centre tuning and improved anti roll bars we were able to run softer a setup so that our improvements in handling do not compromise the ride quality.

Steering is taken care of by a Subaru power rack which gives a quicker ratio than the original rack and is much more readily available than the original TVR rack and at a fraction of the cost.

We have explored various options for coatings and have settled on a standard process of; full sand blast, zinc epoxy primer powder coat and epoxy powder gloss coat in any standard RAL colour.

Engine and Gearbox Choice

The chassis was developed alongside our GM LS3 Engine and Tremec 6 speed gearbox installation, a wider engine bay was therefore a must to allow us to develop the correct size exhaust manifolds which could be routed down the side of the engine rather than the traditional forward system which puts all the exhaust heat into the engine bay and causes major problems packaging ancillaries onto the engine.

From our experience of fitting these engines and gearboxes into standard chassis’ we knew where we needed more space for the exhausts and gearbox, tubes that were in the way that needed to be re-routed and also how we could incorporate the install and make it work more as part of the chassis, for instance our new engine mounts are much more substantial and are designed to hold the engine rather than just have it sit in the engine bay, our new gearbox mount is a bolt in cross member which ties the bottom chassis rails together rather than two separate independent mounts that the gearbox just sits on.

The Complete Package

In conclusion, a dramatically improved chassis, with greater structural and torsional rigidity, better impact protection, greatly improved suspension geometry for more predictable handling, controlled steering and constant grip is achieved. The improved geometry allows the use of larger wheels and better tyre profiles and in turn larger brakes. High quality materials and surface coatings for greater longevity and a chassis that is designed to carry and handle the substantially increased power of the Rover V8’s successor, the GM LS3.

If your car needs a new chassis or you need more power, why now would you opt for a replacement standard chassis? Please contact us for more details and prices and availability. Demonstrators will be available soon!

LS Engine Upgrades

We have now been installing Chevrolet’s LS V8 engines to TVR sports cars since 2009 and now fit brand new LS3 crate engines.